to meet the specific needs and tolerances

of your custom stainless steel parts.

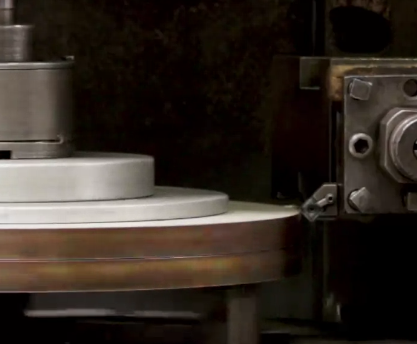

Stainless Plate Products, Inc. started out as a traditional machine shop and, although technology has made considerable advances since then, we still employ traditional machining tools everyday. When the job, product or part requires the turnaround time and economy of machine cutting, SPP can cut and machine stainless plate up to 120".

Stainless Plate Products, Inc. started out as a traditional machine shop and, although technology has made considerable advances since then, we still employ traditional machining tools everyday. When the job, product or part requires the turnaround time and economy of machine cutting, SPP can cut and machine stainless plate up to 120".

Operation

The entire machining process takes place at a single workstation where a flange can be cut, drilled and finished, saving the customer time and money. For most simple rings and discs, machine cut is a better choice because it is cheaper and quicker to produce than water jet.

One Process Does Not Fit All

In some cases, it makes sense to use multiple processes. As an integrated processor we have the ability to use multiple methods to produce the best result without the additional cost and delay of sending jobs out for secondary operations.

Requirements

Machine cut is required for pipe and specialty flanges and for pieces that require the following:

AWWA flanges

Gasket surfaces

125-250 RMS surface finishes

Raised face details

Precision drilling

Tapped holes

Counterbores

O-Ring grooves

| Process | Max. Gauge | Cut Quality |

Cut Tolerance |

Delivery Turn-around |

Heat Affected Zone |

| Machine Cut | Any | ||||

| Nitrogen Plasma | 3" | ||||

| Argon Plasma | 6 1/2" | ||||

| HD Plasma | 6" | ||||

| Water Jet | Any | ||||

| Bevel Cut | Any |

Depending on the finish dimensions, type, gauge and intended use, there are usually a number of ways to produce any given part or shape. Each method has its advantages and our experienced sales team is ready to help you select the cutting option with the best quality, delivery and overall value for your application.

Unsure which is the best choice for your stainless plate products?

Let SPP help you choose the best method for your parts. Contact us today!