to meet the specific needs and tolerances

of your custom stainless steel parts.

Stainless steel plates are a commodity. Certainly, only specialized shops can deal with larger physical sizes and depths, but the real difference between Stainless Plate Products, Inc. and our competitors is in our processes and customer service. Continually evolving, each capability is a specialty at SPP, and that includes sales and service. We invest in new technologies and improve our processes all the time, for one reason—to give the customer the best stainless experience possible.

Like our name says, Stainless Plate Products, Inc. specializes in developing products from stainless steel plate. An American-owned and operated company, SPP USA inventories an impressive assortment of material variety and volume. When required we can offer mill certified Defense Federal Acquisition Regulations (DFARS) and NACE (MO175) material.

We develop products by employing water jet cutting, plasma cutting, machining and bevel cutting processes that deliver products to our customer's exacting specifications.

It’s important to understand the differences in SPP’s processes. Here’s an overview with links to dig deeper for more detail and clarification on each process.

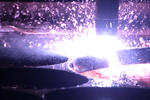

PLASMA CUTTING

Plasma cutting is a process that is used to cut steel and other metals of different thicknesses (or sometimes other materials) using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma.

Learn more about PLASMA CUTTING ![]()

MACHINE CUTTING

MACHINE CUTTING

Machine cutting uses traditional machine shop tools to complete the job to the customer's specifications. Often faster and less expensive, machine cutting includes the ability to drill, tap and machine all parts of a stainless steel plate.

Learn more about MACHINE CUTTING ![]()

WATER JET CUTTING

WATER JET CUTTING

A water jet cutter is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasivejet refers specifically to the use of a mixture of water and abrasive to cut materials like stainless steel. Water jet cutting is often used during fabrication of machine parts and is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods. Water jet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.

Learn more about WATER JET CUTTING ![]()

BEVEL CUTTING

BEVEL CUTTING

Stainless Plate Products' beveling cuts, executed in-line as part of the product fabrication process, is achieved with SPP's plasma torch machines. Various types of bevel cuts are available for your product and, as always, SPP is focused on quality results from plan drawing to deliverable.

Learn more about BEVEL CUTTING ![]()

| Process | Max. Gauge | Cut Quality |

Cut Tolerance |

Delivery Turn-around |

Heat Affected Zone |

| Machine Cut | Any | ||||

| Nitrogen Plasma | 3" | ||||

| Argon Plasma | 6 1/2" | ||||

| HD Plasma | 6" | ||||

| Water Jet | Any | ||||

| Bevel Cut | Any |

Depending on the finish dimensions, type, gauge and intended use, there are usually a number of ways to produce any given part or shape. Each method has its advantages and our experienced sales team is ready to help you select the cutting option with the best quality, delivery and overall value for your application.

SPP adds even more value by getting your parts ready to use when they arrive to you with the below value added processes that can save you time and money. Review our capabilities and contact us to learn how we can improve your next order.

Polishing

Standard Finishes

• #3 (80-100Ra)

• #4 (28-35Ra)

• #6 (10-20Ra)

• #7 (4-9, dull mirror)

Surface Protection

Press Flattening

Traceability Reports

Unsure which is the best choice for your stainless plate products?

Let SPP help you choose the best method for your parts. Contact us today!