types and grades.

Stainless steels are primarily used when corrosion or oxidation is a problem. The function that they perform cannot be duplicated by other materials for their cost. Over 50 years ago, it was discovered that a minimum of 12% chromium would impart corrosion and oxidation resistance to steel. Hence the definition “Stainless Steels”, are those ferrous alloys that contain a minimum of 12% chromium for corrosion resistance. This development was the start of a family of alloys which has enabled the advancement and growth of chemical processing and power generating systems upon which our technological society is based.

Subsequently several important sub-categories of stainless steels have been developed. The sub-categories are austenitic, martensitic, ferritic, duplex, precipitation hardening and super alloys.

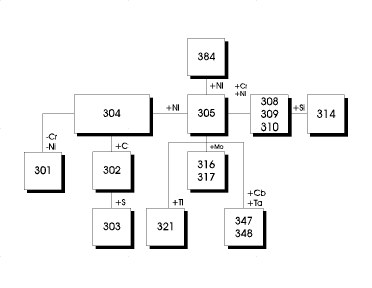

Austenitic grades are those alloys which are commonly in use for stainless applications. The austenitic grades are not magnetic. The most common austenitic alloys are iron-chromium-nickel steels and are widely known as the 300 series. The austenitic stainless steels, because of their high chromium and nickel content, are the most corrosion resistant of the stainless group providing unusually fine mechanical properties. They cannot be hardened by heat treatment, but can be hardened significantly by cold-working.

Figure 1 - Austenitic Grades

Straight Grades

The straight grades of austenitic stainless steel contain a maximum of .08% carbon. There is a misconception that straight grades contain a minimum of .03% carbon, but the spec does not require this. As long as the material meets the physical requirements of straight grade, there is no minimum carbon requirement.

Low Carbon Grades

The “L” grades are used to provide extra corrosion resistance after welding. The letter “L” after a stainless steel type indicates low carbon (as in 304L). The carbon is kept to .03% or under to avoid carbide precipitation. Carbon in steel when heated to temperatures in what is called the critical range (800 degrees F to 1600 degrees F) precipitates out, combines with the chromium and gathers on the grain boundaries. This deprives the steel of the chromium in solution and promotes corrosion adjacent to the grain boundaries. By controlling the amount of carbon, this is minimized. For weldability, the “L” grades are used. You may ask why all stainless steels are not produced as “L” grades. There are a couple of reasons:

"L" grades are more expensive

Carbon at high temperatures imparts great physical strength

Frequently the mills are buying their raw material in “L” grades, but specifying the physical properties of the straight grade to retain straight grade strength. A case of having your cake and heating it too. This results in the material being dual certified 304/304L; 316/316L, etc.

High Carbon Grades

The “H” grades contain a minimum of .04% carbon and a maximum of .10% carbon and are designated by the letter “H” after the alloy. People ask for “H” grades primarily when the material will be used at extreme temperatures as the higher carbon helps the material retain strength at extreme temperatures.

You may hear the phrase “solution annealing”. This means only that the carbides which may have precipitated (or moved) to the grain boundaries are put back into solution (dispersed) into the matrix of the metal by the annealing process. “L” grades are used where annealing after welding is impractical, such as in the field where pipe and fittings are being welded.

Type 304 | The most common of austenitic grades, containing approximately 18% chromium and 8% nickel. It is used for chemical processing equipment, for food, dairy, and beverage industries, for heat exchangers, and for the milder chemicals. |

Type 316 | Contains 16% to 18% chromium and 11% to 14% nickel. It also has molybdenum added to the nickel and chrome of the 304. The molybdenum is used to control pit type attack. Type 316 is used in chemical processing, the pulp and paper industry, for food and beverage processing and dispensing and in the more corrosive environments. The molybdenum must be a minimum of 2%. |

Type 317 | Contains a higher percentage of molybdenum than 316 for highly corrosive environments. It must have a minimum of 3% “moly”. It is often used in stacks which contain scrubbers. |

Type 317L | Restricts maximum carbon content to 0.030% max. and silicon to 0.75% max. for extra corrosion resistance. |

Type 317LM | Requires molybdenum content of 4.00% min. |

Type 317LMN | Requires molybdenum content of 4.00% min. and nitrogen of .15% min. |

Type 321 | These types have been developed for corrosive resistance for repeated intermittent exposure to temperature above 800 degrees F. Type 321 is made by the addition of titanium and Type 347 is made by the addition of tantalum/columbium. These grades are primarily used in the aircraft industry. |

Physical and Chemical Properties of Austenitic Grades

More about the physical and chemical properties

of Austenitic Grades of stainless steel can be found HERE.

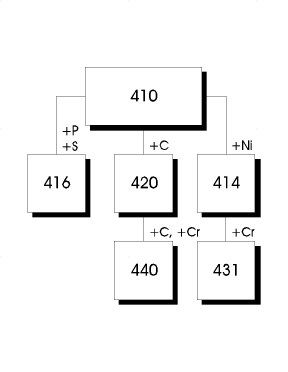

Martensitic grades were developed in order to provide a group of stainless alloys that would be corrosion resistant and hardenable by heat treating. The martensitic grades are straight chromium steels containing no nickel. They are magnetic and can be hardened by heat treating. The martensitic grades are mainly used where hardness, strength, and wear resistance are required.

Figure 2 - Martensitic Grades

Type 410 | Basic martensitic grade, containing the lowest alloy content of the three basic stainless steels (304, 430, and 410). Low cost, general purpose, heat treatable stainless steel. Used widely where corrosion is not severe (air, water, some chemicals, and food acids. Typical applications include highly stressed parts needing the combination of strength and corrosion resistance such as fasteners. |

Type 410S | Contains lower carbon than Type 410, offers improved weldability but lower hardenability. Type 410S is a general purpose corrosion and heat resisting chromium steel recommended for corrosion resisting applications. |

Type 414 | Has nickel added (2%) for improved corrosion resistance. Typical applications include springs and cutlery. |

Type 416 | Contains added phosphorus and sulphur for improved machinability. Typical applications include screw machine parts. |

Type 420 | Contains increased carbon to improve mechanical properties. Typical applications include surgical instruments. |

Type 431 | Contains increased chromium for greater corrosion resistance and good mechanical properties. Typical applications include high strength parts such as valves and pumps. |

Type 440 | Further increases chromium and carbon to improve toughness and corrosion resistance. Typical applications include instruments. |

Physical and Chemical Properties of Martensitic Grades

More about the physical and chemical properties

of Martensitic Grades of stainless steel can be found HERE.

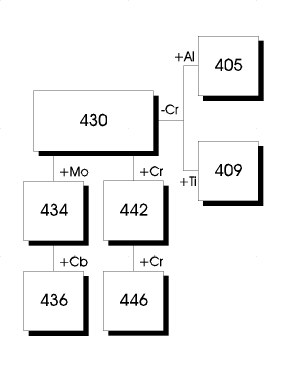

Ferritic grades have been developed to provide a group of stainless steel to resist corrosion and oxidation, while being highly resistant to stress corrosion cracking. These steels are magnetic but cannot be hardened or strengthened by heat treatment. They can be cold worked and softened by annealing. As a group, they are more corrosive resistant than the martensitic grades, but generally inferior to the austenitic grades. Like martensitic grades, these are straight chromium steels with no nickel. They are used for decorative trim, sinks, and automotive applications, particularly exhaust systems.

Figure3 - Ferritic Grades

Type 430 | The basic ferritic grade, with a little less corrosion resistance than Type 304. This type combines high resistance to such corrosives as nitric acid, sulfur gases, and many organic and food acids. |

Type 405 | Has lower chromium and added aluminum to prevent hardening when cooled from high temperatures. Typical applications include heat exchangers. |

Type 409 | Contains the lowest chromium content of all stainless steels and is also the least expensive. Originally designed for muffler stock and also used for exterior parts in non-critical corrosive environments. |

Type 434 | Has molybdenum added for improved corrosion resistance. Typical applications include automotive trim and fasteners. |

Type 436 | Type 436 has columbium added for corrosion and heat resistance. Typical applications include deep-drawn parts. |

Type 442 | Has increased chromium to improve scaling resistance. Typical applications include furnace and heater parts. |

Type 446 | Contains even more chromium added to further improve corrosion and scaling resistance at high temperatures. Especially good for oxidation resistance in sulfuric atmospheres. |

Duplex grades are the newest of the stainless steels. This material is a combination of austenitic and ferritic material. This material has higher strength and superior resistance to stress corrosion cracking. An example of this material is type 2205. It is available on order from the mills.

Precipitation hardening grades, as a class, offer the designer a unique combination of fabricability, strength, ease of heat treatment, and corrosion resistance not found in any other class of material. These grades include 17Cr-4Ni (17-4PH) and 15Cr-5Ni (15-5PH). The austenitic precipitation-hardenable alloys have, to a large extent, been replaced by the more sophisticated and higher strength superalloys. The martensitic precipitation-hardenable stainless steels are really the work horse of the family. While designed primarily as a material to be used for bar, rods, wire, forgings, etc., martensitic precipitation-hardenable alloys are beginning to find more use in the flat rolled form. While the semi-austenitic precipitation-hardenable stainless steels were primarily designed as a sheet and strip product, they have found many applications in other product forms. Developed primarily as aerospace materials, many of these steels are gaining commercial acceptance as truly cost-effective materials in many applications.

Superalloys are used when 316 or 317 are inadequate to withstand attack. They contain very large amounts of nickel and/or chrome and molybdenum. They are usually much more expensive than the usual 300 series alloys and can be more difficult to find. These alloys include Alloy 20 and Hastelloy.